Speak to a member of our team today to discuss your specific requirements

With consumers becoming more aware of the part their buying habits play in protecting the environment, businesses need to adapt, not only to meet demand for more environmentally friendly products and packaging, but also to meet ever more stringent sustainability obligations.

One of the key ways in which many businesses are meeting both buyer demand and recycling and recovery responsibilities, is by avoiding unsustainable options, and using recyclable foam materials as packaging solutions, or as recyclable foam products.

If you’re looking for an experienced recyclable foam supplier, able to supply foam in large or small quantities, look no further than Polyformes, one of the UK’s leading foam manufacturers and converters. With over 40 years’ experience, we have customers across all markets, including, medical, construction, aviation, military, electrical engineering, and TV production.

If you’d like to find out about our complete range of recyclable foam materials, and the processes used to manufacture our high-quality foam products, contact us today either via the website contact form, by phone or by email.

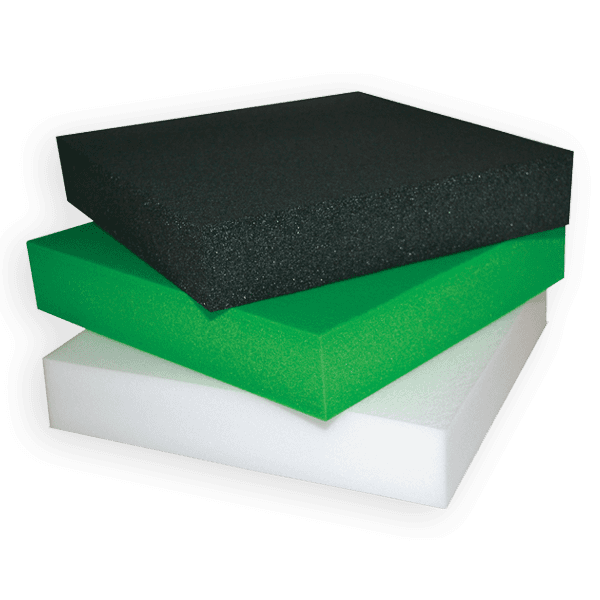

At Polyformes, we provide a whole range of recyclable foam materials, designed to suit the needs of any business. Types of recyclable foam material we supply includes:

Ethafoam – Ethafoam is a medium density, non-cross-linked, expanded, polyethylene recyclable foam. With properties including light-weight, flexibility and impressive shock absorbency, Ethafoam is widely used as a recyclable packaging solution, and in the manufacture of buoyancy aids and electronics components.

Stratocell – As a closed-cell, polyethylene recyclable foam, Stratocell is light-weight, highly water resistant, and has substantial cushioning properties, making it ideal for use as packaging when shipping delicate and damp-averse products.

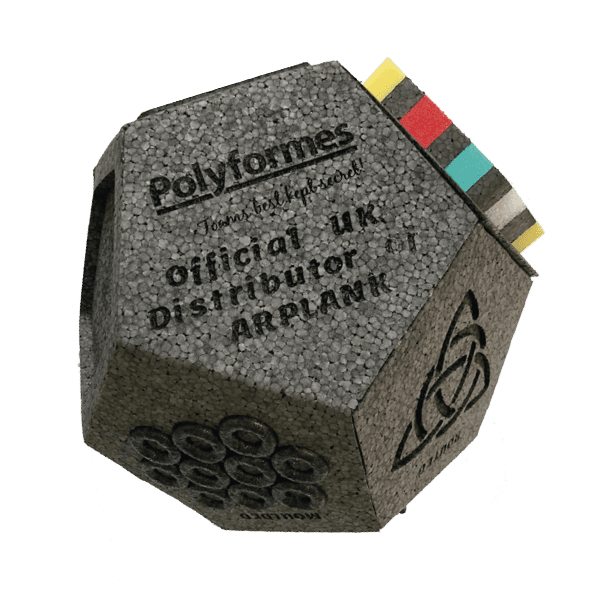

ARPLANK – ARPLANK is a 100% recyclable, closed-cell, bead foam product. Produced without VOC (Volatile Organic Compounds) blowing agents, ARPLANK has a variety of uses, including packaging solutions that require a high-level of shock absorbency and chemical resistance.

Most polyethylene foams can be reused many times over without suffering degradation, but, when it comes to recycling, it’s usually achieved using a hot melting process, with the melted product being turned into pellets to be reused in the manufacture of new foam products.

With research suggesting over 80% of buyers actively seek out sustainable products, why not provide your customers with unique, precision-engineered, recyclable foam products manufactured by Polyformes.

Whichever recyclable foam product you choose, from a recyclable packaging solution, recyclable promotional materials, or gaskets and seals, we’ll ensure each product is developed to your exact specifications, using a variety of modern, state-of-the-art processes, including:

CNC Routing and Machining – A computer-aided cutting and forming technique, that ensures consistency in size, shape and tolerance, every time.

Moulding and Forming – An advanced heat-treating technique, to achieve highly accurate recyclable foam products, used in sectors such as aviation, defence and electrical engineering.

Printing – Using our unique, patented 4 colour printing method, we’ll print vibrant and colourful bespoke designs across all your recyclable foam products.