If you're involved in designing or manufacturing for the aerospace industry in the UK, you know there is little margin for error when it comes to your packaging.

At Polyformes, we offer a wide range of custom packaging solutions for aerospace components, assemblies and tooling. Our protective foams are used throughout the supply chain to prevent damage to high-value, sensitive or complex parts in transit or storage.

The low density closed-cell Plastazote foams are flame retardant and ideal for use in aircraft seating and soft-trim areas. There is usually a significant weight reduction compared to heavier urethane foams or other composite moulded seating. Comfort and durability is also increased as the support and cushioning is better than almost any other material for this application. Polyformes have the skill and experience to fabricate the Plastazote foams in an optimum manner - thermoforming, routing, water-jet cutting and profiling. This capability ensures that ergonomic and economic design is achievable. Special flame retarded grades meet the requirements of FAR/CS 25.853(a) App F Pt.1 and are available in 15, 24 and 45kg/m3 densities.

Polyformes expanded polyethylene foam materials are utilised in so many areas within the aircraft industry. Because they are available in such a wide range of densities and grades, they have manifold applications. Examples include machined packing pieces in LD45 FR Plastazote Charcoal, compression moulded rotor blade spacers in HD115 White Plastazote and routed spacer rings in HD110 Black Plastazote. (The numbers in the nomenclature relate to the material density i.e HD115 is high density polymer 115kg/m3 density foam).

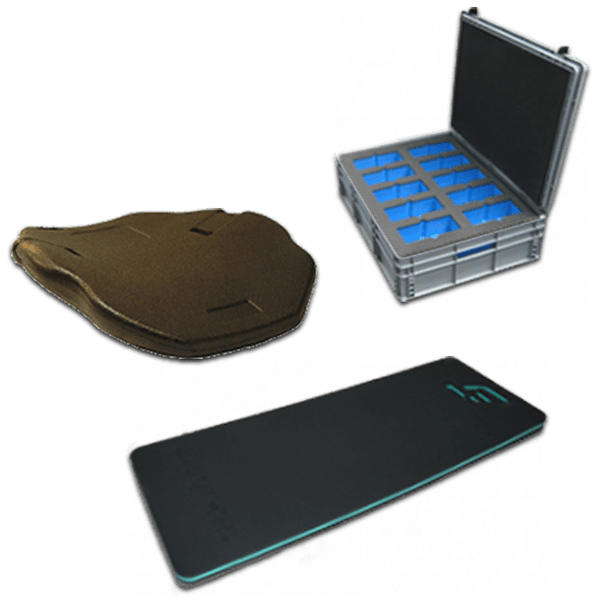

Polyformes foam tray tool control solutions are employed not only by fixed wing and rotary wing aircraft during factory floor assembly, but by the component industries who serve the airspace sector too e.g. aero engine assembly and ejector seat production. Polyformes provides countless tool trays in dual colour foam for this purpose. As well as providing and machining the foam inserts specific to the program or tool requirement, the factory tote tray containers can also be supplied. The foam trays are made from an Azote material - Plastazote LD45 or MP45 for the toughest and most repeatedly used tool trays. The MP45 is resilient, chemical and oil resistant, uv resistant and waterproof, closed-cell pe foam material. There is no higher class of foam for tool control.

When production staff are working on the shop floor, there are times when they are in awkward positions in order to assemble certain parts or systems. Sometimes they are lying beneath a section of aircraft or kneeling in between areas. Polyformes manufactures full size mechanics mats at both single and double width in the same closed cell expanded polyethylene foam. These are durable and highly comfortable. Smaller foam kneelers are invaluable for comfort and protection when kneeling down for any period of time.

With regard to aircraft sections that need to be avoided owing to sensitive cabling or hydraulics, NO STEP port and starboard work mats are produced to suit specific areas. These are a composite high strength ribbed rubber top surface with a pe foam under-section giving safety to personnel and protection to material surfaces.

Tool control is essential in aerospace production and maintenance environments to reduce the risk of foreign object damage.

Polyformes' foam tray tool control solutions are trusted across the aerospace industry—not only by fixed-wing and rotary-wing aircraft manufacturers during factory floor assembly, but also by component suppliers such as those involved in aero engine assembly and ejector seat production. We supply countless dual colour foam tool trays, precisely machined to suit specific tools or program requirements.

Factory tote tray containers can also be supplied with the foam inserts. Our tool trays are made from an Azote material, including Plastazote LD45 and MP45, for the toughest and most repeatedly used tool trays. The MP45 is a durable closed-cell PE foam that is resilient, chemical and oil resistant, uv resistant and waterproof.

There is no higher class foam available for tool control applications, providing excellent durability, performance and protection in even the most demanding aerospace environments.

When production staff are working on the shop floor, they often find themselves in awkward or constrained positions to assemble critical aircraft parts or systems. Whether lying beneath a section of an aircraft or kneeling between tight spaces.

Polyformes manufacturers full size mechanics mats to support these working conditions. Available in both single and double width, using the same closed-cell expanded polyethylene foam known for its comfort and durability.

Smaller foam kneelers offer invaluable comfort and protection for engineers and technicians when kneeling down for extended periods of time, helping reduce fatigue and improve ergonomics.

For aircraft sections that must be avoided due to sensitive cabling or hydraulics, NO STEP port and starboard work mats are custom produced to fit specific areas. These mats feature a composite construction, combining a high strength ribbed rubber top surface with a PE foam under-section, giving safety to personnel and protection to material surfaces.

Many aircraft components are oversized, fragile or have irregular geometries. Polyformes can design and manufacture custom packaging solutions for large aerospace parts, including fuselage panels, wing sections, engine components, seating, crew equipment, and more.

We utilise a range of foam densities and compositions to provide optimal shock absorption, compression resistance and part immobilisation, with optional integration into custom-built cases or crates.

At Polyformes, our commitment to the aerospace sector goes beyond materials—we offer bespoke foam engineering solutions tailored to each application. Every solution is backed by our experience, exacting quality standards, and agile UK-based manufacturing.

We work closely with businesses to develop application-specific foam solutions across commercial, military, and private aviation sectors. Whether it's prototyping a new seat component, creating protective packaging for composite assemblies, or helping design tooling trays for an MRO hangar. Our engineering approach provides your packaging with high-performance protection for your specific application.