ARPLANK is made from 30% recycled material and, in turn, can be 100% recycled.

ARPLANK offers excellent shock absorption and repeated shock resistance.

Its optimal density makes ARPLANK a volume-reduced, lighter and safer packaging option.

Very good isothermal properties. ARPLANK is stable from -60 to 100 C.

ARPLANK is chemically inert; free of chemicals and volatile organic compounds (VOC).

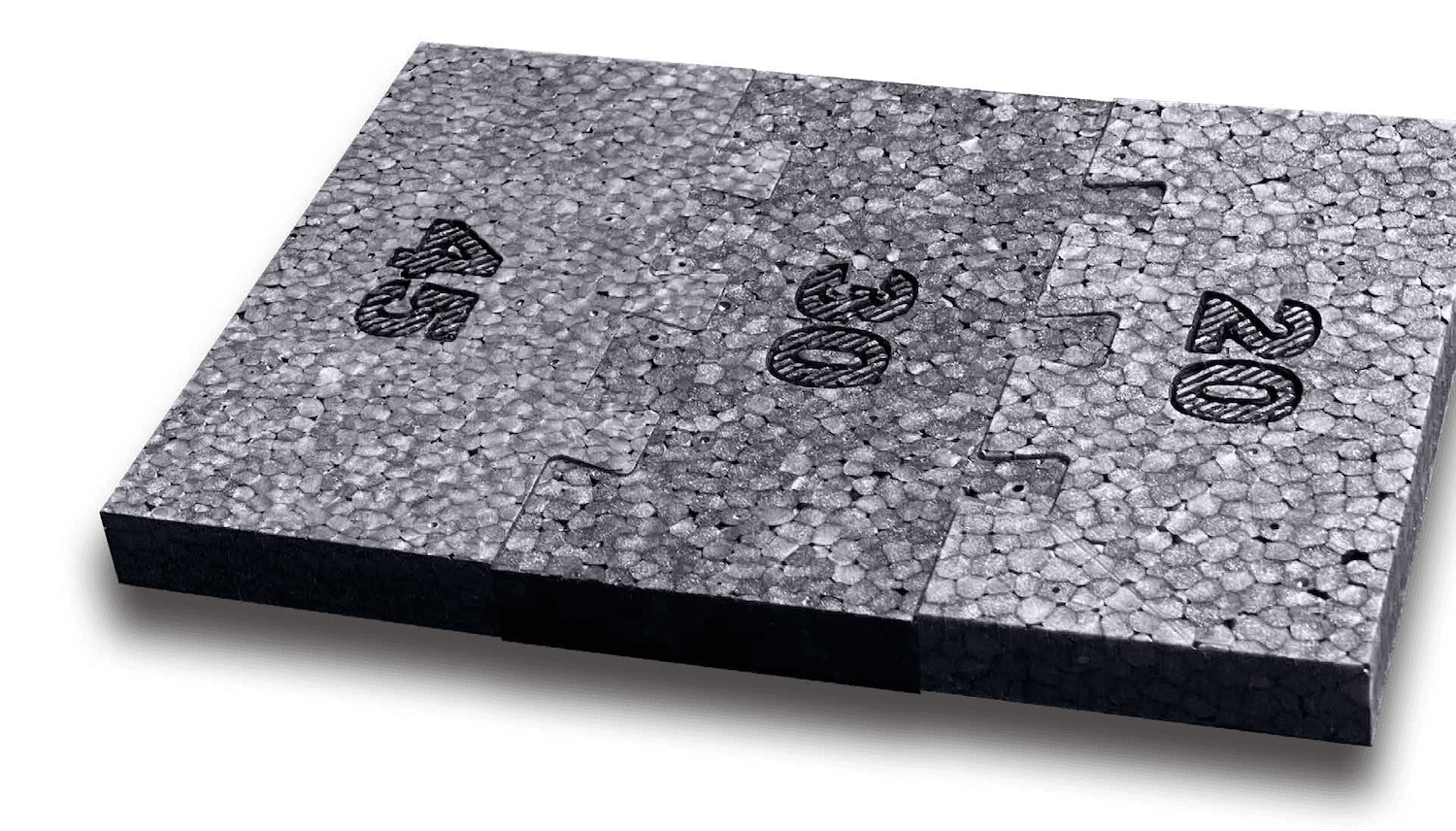

ARPLANK is an isotropic block material - the same energy absorption across all three planes.

A 30kg/m3 Conductive option is available with a surface resistance of ≤10⁵ Ω (Ohm)

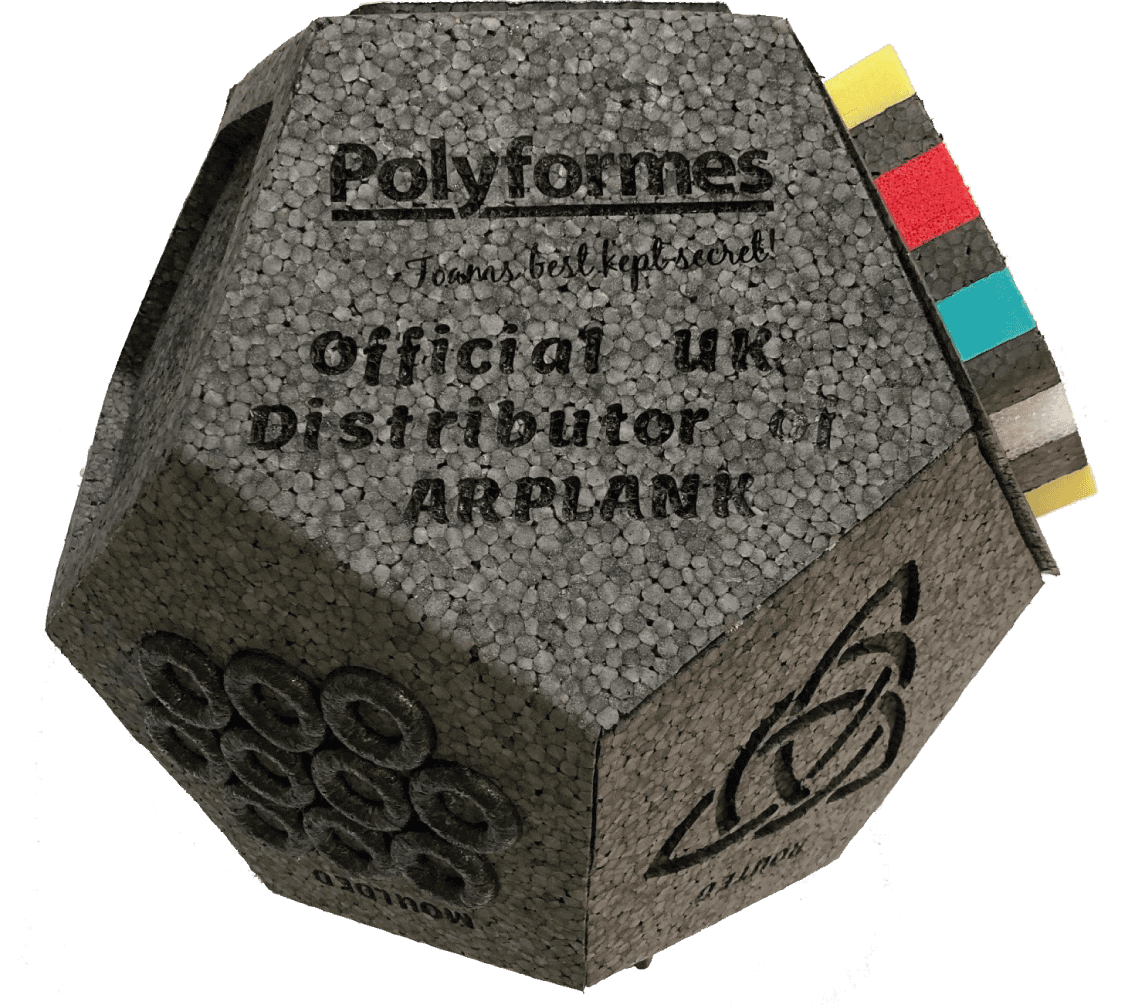

The 100% Recyclable, highly resilient closed-cell material, made from expanded polyethylene (EPE) bead foam.

It is the ideal product for applications such as packaging and cushioning, expandable and returnable dunnage, thermal management and flotation.

Made in Europe and exclusively distributed by ourselves in the UK, the ARPLANK material is made from 30% recycled material.

It is one of the most effective packaging materials on the market, with the ability to absorb multiple impacts as well as being sustainable and lightweight. The thermally bonded polyethylene beads create a three-dimensional performance that absorbs and dissipates energy.

This isotropic behaviour means ARPLANK is multidirectional in nature. This same performance in all 3 axes combined with its fine surface protects surface-sensitive or painted goods and makes it an ideal product for protective packaging applications.

Now with the 30kg/m3 Conductive option it opens itself up to being effective in the protection of sensitive products requiring ESD (electro-static discharge) protection in the electronics, automotive, solar and photovoltaics industries.

The material is being used to make load carriers, CKD (Complete Knock Down) packaging, structural packaging, inserts and also die-cut products. ARPLANK can be fabricated by commonly used operations such as die cutting, splitting, water jet, laser, CNC milling, sawing and moulding.

ARPLANK is an energy absorbing cushioning material for products requiring shock absorption, vibration dampening, insulation and chemical resistance. This versatility makes it ideal for protective packaging applications.

DENSITY OPTIMISATION

30-40% smaller, lighter and safer packaging option

ISOTROPIC BLOCKS

The same impact performance from all 3 axes

CHEMICALLY INERT

No chemicals used during production and no VOC. Water and oil resistant

HIGH SHOCK ABSORPTION

Multi-directional compression, unaffected by the direction of impact

WIDE TEMPERATURE RANGE

High temperature range from -60 to 100°C

100% RECYCLABLE

Made from 30% recycled material in Europe and fully recyclable.

ARPLANK Brochure

ARPLANK Chemical Resistance

ARPLANK Substances Regulations

ARPLANK Press Release

Simbodies Press Release

ARPLANK Test Results

Test Report: RES 226679 (part 1)

Test Report: RES 226679 (part 2)

Test Report: RES 226679 (part 3)

Test Report: RES 226679 (part 4)

Test to ROHS Directive 2011/65/EU

Water Absorption Test Report

The densities that ARPLANK is available in, has the cushioning properties and compression set that competes with XPE.