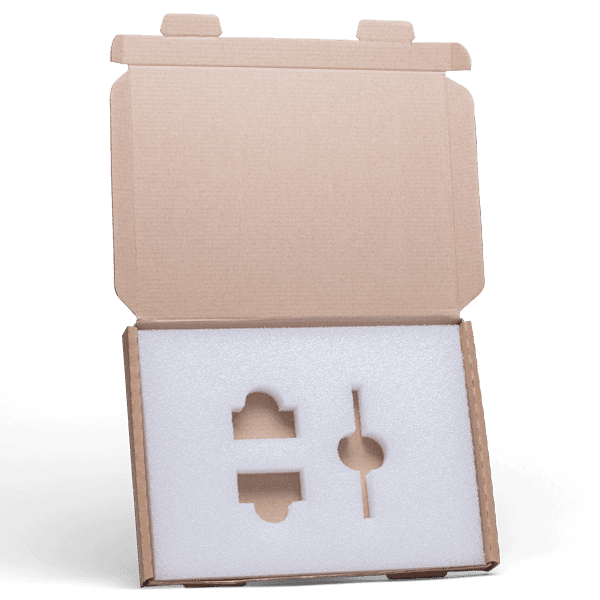

What Are Bespoke Foam Inserts?

Polyformes bespoke foam inserts are foam inserts specifically created for boxes, cases and other types of enclosures. Manufactured from high-quality, closed-cell foam material, these precision-cut, custom-designed foam inserts, protect your product or equipment from damage caused by:

- Impact and vibration, especially during transit

- Extremes of temperature

- Moisture exposure

- Chemical exposure

How Custom Foam Packaging Inserts Protect

Custom foam packaging inserts from Polyformes, protect your product by creating a close surrounding of protective foam packaging. Our solutions have a range of innate properties, including:

-

Impact resistance: This property, common to all foam materials used for our custom foam packaging inserts, is due to the closed-cell structure of the foam, where each cell traps air or gas, which in turn gives the foam exceptional impact absorption, and the ability to spring back to its original shape.

-

Vibration control: The same closed-cell structure of the foam we use for packaging inserts, which protects objects from impact damage, also acts to massively reduce the effect of constant vibration, by creating a custom fit around the object, providing a controlled, vibration absorption effect.

-

Resistance against extremes of temperature: The foam materials we use at Polyformes for your protective foam packaging inserts, such as Plastazote and ARPLANK etc., are known for the exceptional protection they provide against both extremes of heat and cold, and how they help to regulate the temperature surrounding your product.

-

Resistance to chemical exposure: Many commercial products and much of the commercial equipment we need to transport can be seriously affected when exposed to certain chemicals. That’s why all the foam materials used for our custom foam inserts are chemically inert and highly resistant to commonly used chemicals.

-

Resistance to water and moisture: Accidental water and moisture damage during transportation of products and vital equipment cost businesses millions. That’s why, the foam we use to make your bespoke foam inserts, provides the perfect barrier, even from the effect of high volumes of water exposure.

How We Manufacture Your Bespoke Foam Inserts

Manufacturing your bespoke foam inserts will usually begin with a consultation with a foam expert, to find out exactly what you’d like to achieve with your bespoke foam inserts, the volume required, when you’d like the project delivered and other specifications.

The next step will be the design stage, where our expert foam converters will design your custom foam inserts using the latest design technology and techniques, ensuring the design achieves the protection, and look you require.

The last stage of manufacturing your bespoke foam inserts is the cutting and forming stage, where we bring your designs to life using the selected foam material, and various, state-of-the-art and traditional cutting and forming techniques, which include:

-

CNC Routing and Machining: CNC (Computer Numerical Control) machining is a computer-controlled cutting process, using various shaped machine heads to precisely cut your bespoke foam inserts to the shape you require and at the high tolerances you expect.

-

Moulding and Forming: Both Thermoforming and Compression Moulding are techniques to mould and form the intricate details of your custom foam inserts, to help attain the high level of protection and aesthetic appearance your product requires.

-

Printing: As part of the cutting and forming process of your bespoke foam inserts, we also offer a foam printing service, where using our patented 4 colour printing technique, we’ll print graphics, logos and text on your bespoke foam inserts, in the rich, high-definition colours of your choice.