Ensure operational efficiency and safety with Polyformes' custom tool control foam shadowboards. Our bespoke foam inserts are designed to fit your tools perfectly, providing clear visual indicators to prevent loss and enhance productivity.

Tool control is a measure of ensuring safety, efficiency, improved productivity and savings within the factory or workplace environment, especially in the aerospace and automotive fields. With a simple and highly effective method of instantly seeing that all of the required tools for the required job are in place, work can begin in the knowledge that the job or shift should be free of any tooling issues.

The benefits of having properly organised tool storage and control include:

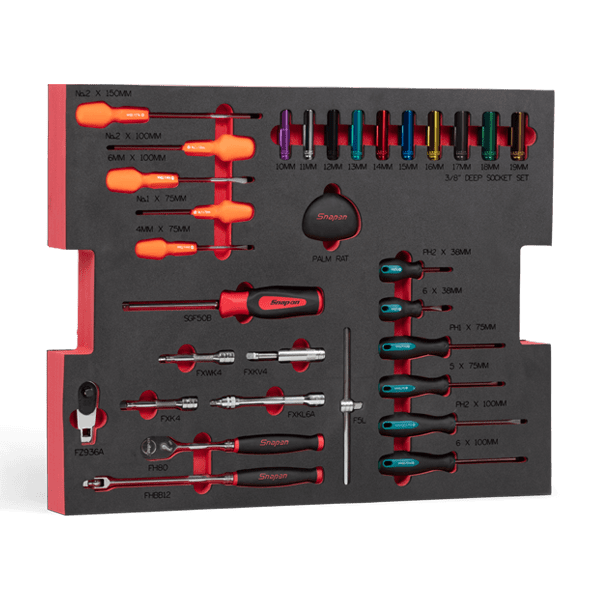

To assist in the effectiveness of tool control, the foam drawer or tool cabinet inserts are often made in dual colour material. This makes it even quicker to see if a tool is not in position. The foams used for tool control trays will usually be closed cell foam, and the most consistent foams to use are part of the Azote family - Plastazote. Plastazote is a cross-linked expanded polyethylene, and it is this cross-linking of the individual cells which gives it extra strength, uniformity and durability whilst offering optimum cushioning properties. Plastazote foam inserts are resistant to oils and chemicals and can be laser marked at each individual pocket to identify the tool or part by number or size as added security. Company logos can also be engraved.

At Polyformes, we employ advanced design techniques to create foam inserts that perfectly match the contours of your tools. Our use of Plastazote® foam offers:

Chemical Resistance: Ideal for environments where exposure to oils and chemicals is common.

Moisture Resistance: Protects tools from corrosion due to humidity.

Custom Branding: Options for laser etching logos, part numbers, or instructions directly onto the foam surface.

Dual-Colour Foam Layers: Enhance visibility and tool identification.

Laser Etching: Add logos, part numbers, or instructions for easy identification.

Various Foam Densities: Choose the appropriate density to match the fragility and weight of your tools.

Utilise dual-colour foam layers to create a shadow effect, making it immediately apparent when a tool is missing. This visual cue helps in quick identification and replacement, reducing downtime.

Our foam inserts are crafted from high-quality materials like Plastazote® (cross-linked polyethylene), known for its durability, chemical resistance and cushioning properties. This makes sure your tools remain in pristine condition, even under rigorous use.

Whether you're in aerospace, automotive, electronics or general manufacturing, our shadowboards are customisable to meet the specific needs of your industry for maximum efficiency and safety.

Aerospace & Defence: Ensure compliance and safety standards are met with precise tool control.

Automotive: Streamline maintenance and repair processes with organized tool storage.

Electronics: Protect sensitive components during assembly and testing.

Manufacturing: Improve assembly line efficiency with readily accessible tools.

1. Consultation

Discuss your specific requirements and tool specifications.

2. Design

Create a custom design using CAD software to ensure a perfect fit.

3. Prototype

Develop a sample for approval before full-scale production.

4. Production

Manufacture the final product using high-quality materials.

5. Delivery

Ensure timely delivery to your location.

Ready to protect your investment?

(or upload your drawings) and let's design your ideal case insert.